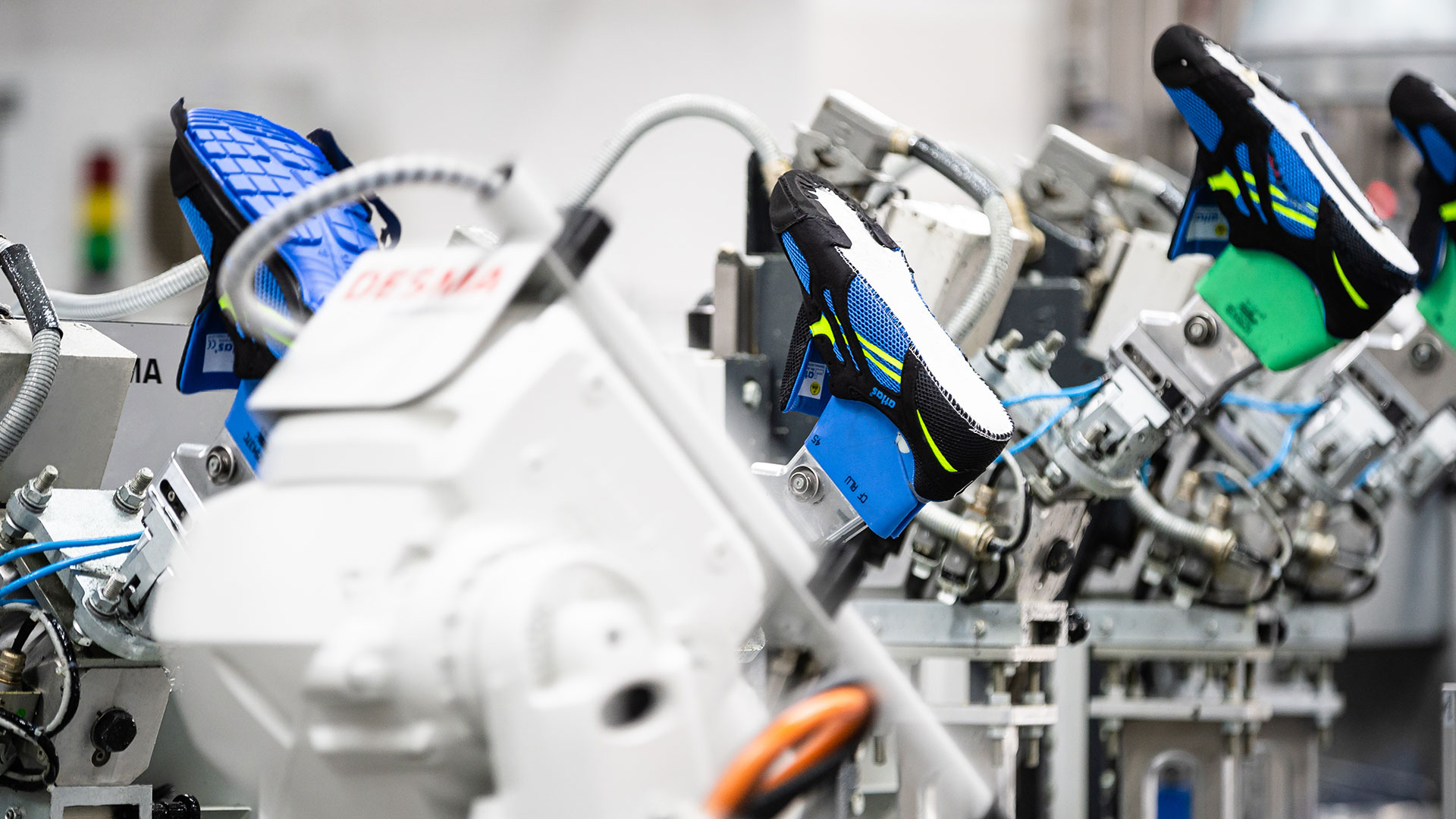

With the new PU direct injection system, your safety shoe manufacturer can now respond even more quickly to its customers’ wishes and produce up to 3,000 pairs of safety shoes more per day with this new machine. A total of 3 employees per shift collaborate with 8 robots to guarantee the highest precision and manufacturing quality. A multi-functional polyurethane foam, for short: MPU®, is the basis for the ATLAS® high-tech sole system with this machine, as well. The two-layer make-up of outer sole and midsole reveals the material’s exceptional properties. The combination of a very abrasion-resistant outer sole and an extremely energy-absorbing as well as stabilising midsole creates a feeling of perfect safety for the wearer.