ADDING SOLIDS TO THE PRODUCTION CYCLE

Midsole

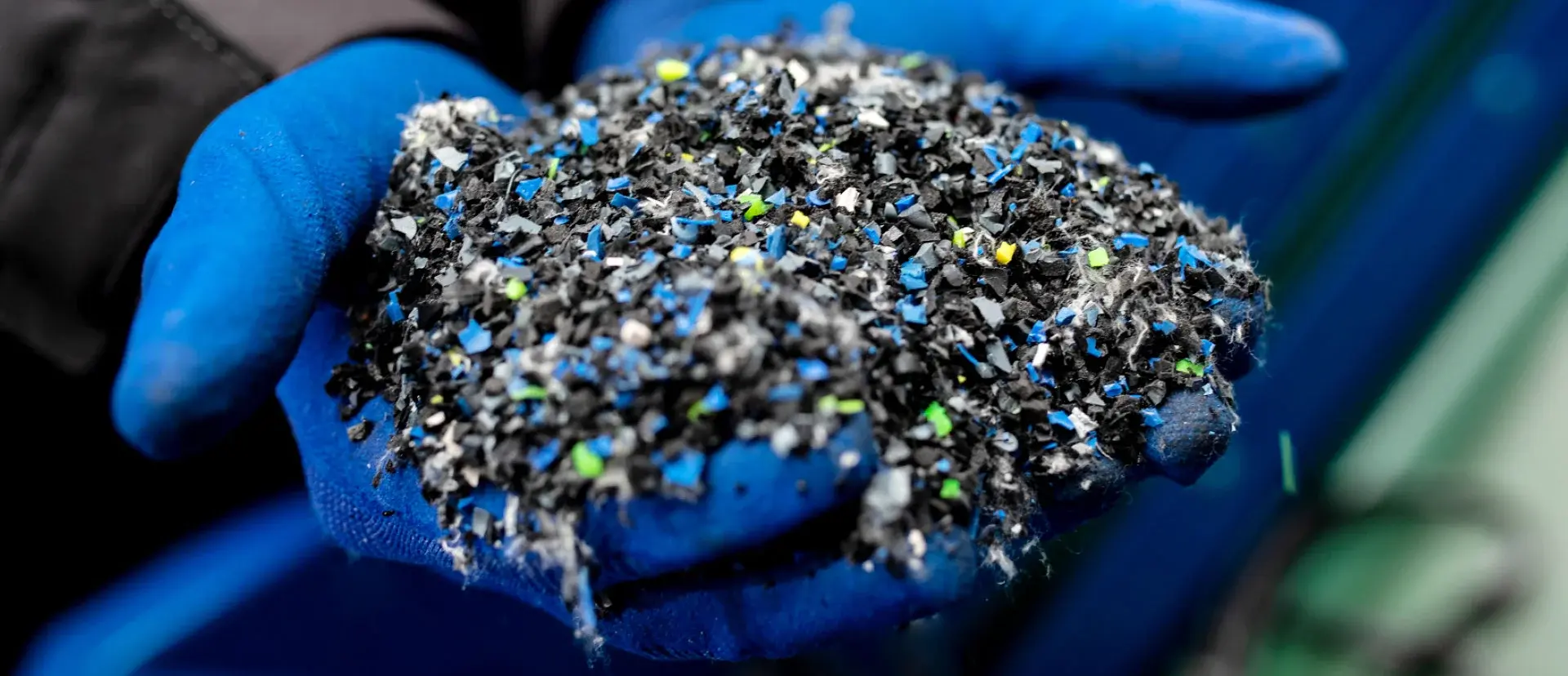

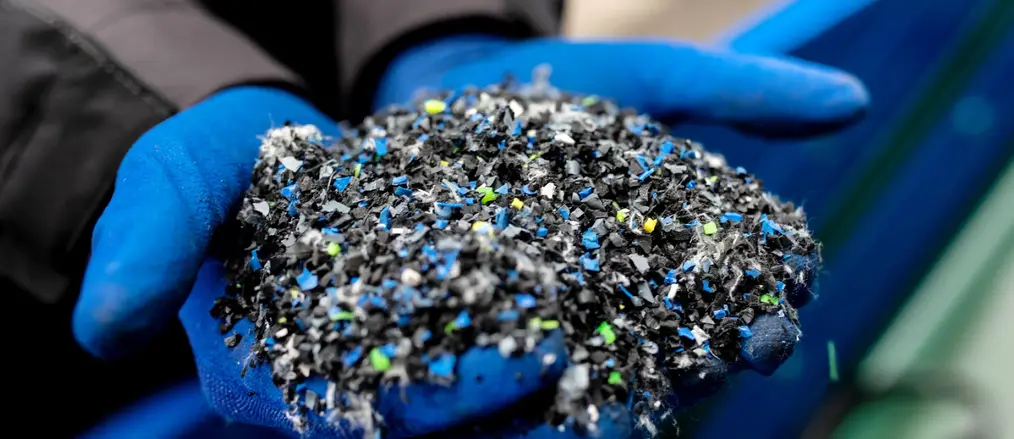

Adding solids to the production cycle to reduce the use of raw materials

Production waste naturally occurs during the manufacture of the midsole in the direct soling system. We now collect these PU residues, granulate them and return them to the production cycle. 20% of the midsole of the Recycling Safety Shoe consists of added solids due to this process. In the midsole production of a single shoe, we can therefore save one fifth of primary materials and thus reduce the use of raw materials (polyol and isocyanate).

From left to right: THOMAS LANZKI (CSR Manager), HENDRIK SCHABSKY (CEO ATLAS), MAXIMILIAN SCHULTE (CSR Project Manager)

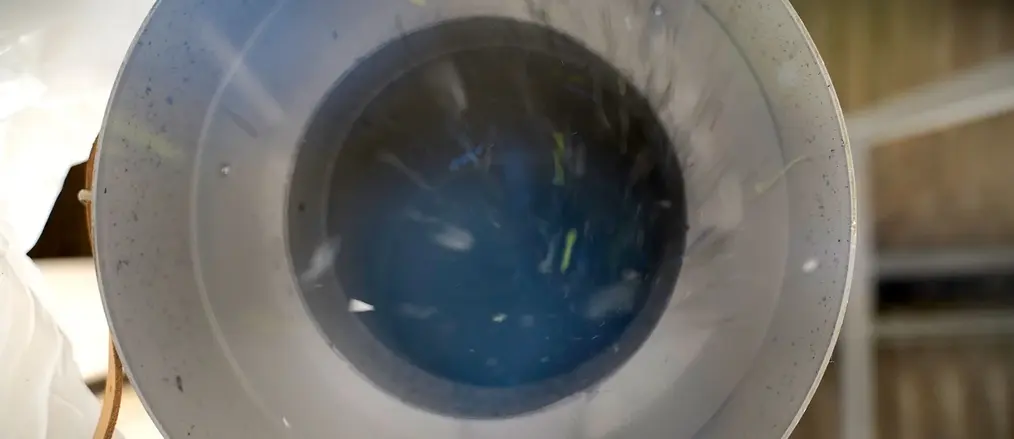

MPU® CUTTER

- Addition of granulated ATLAS PU production residues

- Return to the production cycle

- Reduction of primary materials

- Unique in the safety shoe industry